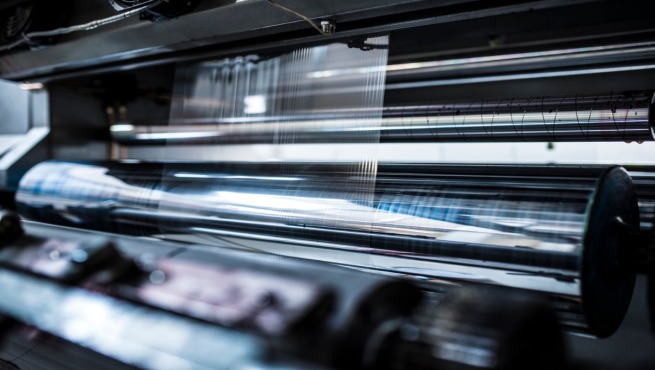

For most people, wrinkles are a sign of wisdom and a simple fact of life. For those in the engineered plastic film converting industry, wrinkles are a far scarier proposition.

That’s because, for a converter, a wrinkle in a roll of plastic film is like a ten-car pile-up waiting to happen. Once that wrinkle finds its way from the roll into a converter’s processes, machines start to shutdown, raw material is wasted and downtime cascades throughout the shop floor.

These experiences are something most plastic film converters would rather avoid.

And that’s why companies like Inteplast Engineered Films (IEF) put a premium on investing in new technology and capital equipment.

Continuous Improvement

“We've seen in the last twenty years incredible advancements in the converter equipment used in the engineered plastic film industry,” says John Richards, IEF’s Technical & Quality Manager.

This technology, says Richards, has forced blown film producers to pay a lot more attention to product quality and film gauge, because high-quality film allows the new converting equipment to operate at its most optimum rate.

“It's moved the needle on the expectation of the quality standards back down the supply chain,” says Richards. “On a large campaign, our customers want to see less than 5 percent gauge variation from point to point, so they can hang a roll and run it at 1,200 feet-per-minute and have no issues whatsoever.”

In an effort to stay ahead, IEF has been continuing its investments in new equipment for the last five years on more than twenty-five processing lines, and it is adding new lines over the next six months.

Adam Furtado, Product Manager, Engineered Films at Inteplast Group in Boston, says capital investment is something a company has to do over time to improve the product and the process. “You improve this line, you improve that line, you do it to create a better product offering overall.”

“Its important to us to ensure our partners don't have any disruptions when they're processing film, they don't have any issues when they're filling packages, and when they're laminating it runs seamlessly,” he says. “It comes down to us originally blowing the film. We understand we are a key part of our partners’ success. That’s why we have a fairly aggressive plan across all six sites.”

Delivering Value

This investment plan goes hand-in-hand with the sector’s increasing dependence on just-in-time production. Richards says IEF’s partners in the sector have little inventory, keep their forecasting tight and their lead times short.

It’s a demanding process, but delivers a great deal of value when done right. In fact, it has become so important that IEF has implemented just-in-time as well, something Richards slyly refers to as “on the core, out the door.”

Published August 2018